275/P 600A

Automatic bollards with integrated hydraulic unit

Variant of the Pilomat Series P Line, designed for intelligent management of urban traffic in high-intensity contexts.

The automatic bollard 275/P 600A is one of the best-sellers in the Pilomat range.

Available in steel, stone and stainless steel, it offers greater resistance than the 127/P and 220/P versions. It can be installed with an inclination, has TüV-certified impact resistance, an RGB LED strip, and is available with an optional removable pump. The 275/P 600A model was one of the pioneering products in public safety: it is the first in Italy to have received approval from the Ministry of Infrastructure and Transport, the Department for Land Transport and the Directorate-General for Motor Vehicles. This makes it the best solution for public administrations, which can install it throughout Italy without further authorizations.

This product is also effectively used as an anti-intrusion system and deterrent against theft. It is also perfect for integration with other access-control systems such as barriers and gates.

Certifications

Impact Resistance Verified

Application areas

Standard configuration

Vehicle access control device in anthracite grey painted steel.

Underground structure housing the bollard.

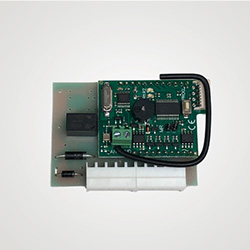

Manages the operation of the bollard.

Technical data

|

Cylinder material |

S235JR normal steel - X5CrNi 18-10 (AISI 304) - X5CrNiMo 17-12-2 (AISI 316) stainless steel |

|

Cylinder diameter |

273mm |

|

Cylinder height |

600mm |

|

Cylinder thickness |

6mm (optional AISI 316: 4mm) |

|

Movement principle |

Hydraulic |

|

Cylinder normal steel finish |

Anti-corrosion treatment - grey anthracite standard painting |

|

Cylinder stainless steel finish |

Grey anthracite standard painting or brushing |

|

Reflecting adhesive strip |

Standard - height 55mm |

|

Rising time |

3,5s |

|

Lowering time |

2s |

|

Emergency lowering |

Standard (optional: automatic lowering) |

|

Safety reversal |

Standard |

|

Connection line to control unit |

Standard 10m (max 80m - with heating element max 50m) |

|

Voltage for control unit |

230/400 VAC (+/- 10%) 50/60Hz |

|

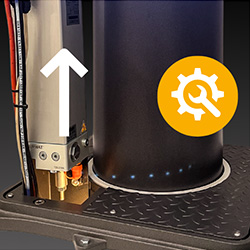

Hydraulic pump |

Built-in the bollard |

|

Protection class |

IP 67 |

|

Type of use |

2000 Cycles/day |

|

Life units |

3.000.000 Cycles |

|

Impact resistance |

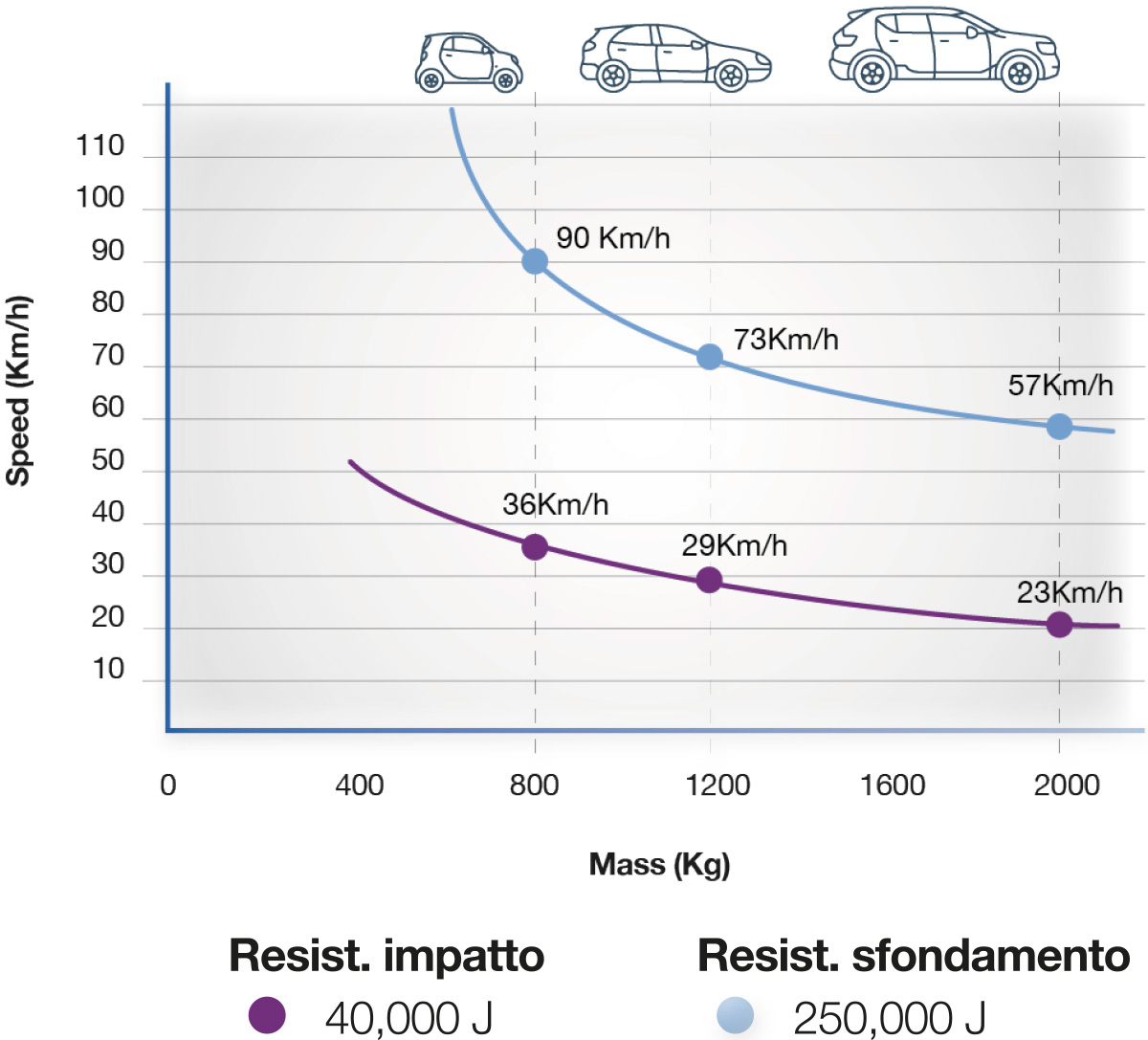

40.000 J (approved by TÜV Rheinland) |

|

Breakout resistance |

250.000 J |

|

Nominal operating temperature |

-40°C +70°C (for low temperatures see heating resistance) |

|

Load class (EN124) |

D400 |

Dimensions

Crash test

Available finishes

-

RAL painting

-

Brushing

-

Knurling

-

Stone mantle

-

Anti-corrosion marine treatment

Safety and visibility

-

Reflecting strip

-

LED lighting strip

-

Warning signal

-

Safety reverse function

-

Traffic light

-

Induction loops

Special design

-

Custom cover plate

-

RAL painted cover

-

Custom inclination

-

Frame for paving stones

-

Full inox

Functions

-

Full inox

-

Heating element

-

UPS unit

-

Extractable hydraulic unit

-

Sensors: alarm, crash

-

Biodegradable oil

Control devices

-

Key switch

-

Card reader

-

Numeric key pad

-

Finger scan

-

Hand transmitter

-

License plate reader

-

App or Bluetooth

-

Timer (week - year)

-

GSM activator

-

P-Connect

-

Cloud Unit W5-B

Would you like more detailed information about our products and services?

We are at your disposal.