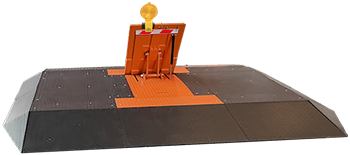

Pilomat,

sinonimo di

dissuasore automatico

Da oltre cinquant’anni, Pilomat è punto di riferimento mondiale nei sistemi per il controllo accessi veicolare. Innovazione tecnologica, affidabilità e design distintivo guidano da sempre la nostra evoluzione, permettendoci di offrire soluzioni su misura per ogni livello di sicurezza, dal residenziale all’antiterrorismo.