Mobile Vehicle Blockers

TEMPORARY SOLUTIONS FOR OUTDOOR EVENTSTemporary solutions such as Road Blocker Mobile and Oktablock regulate access to streets and areas for outdoor events, protecting people from possible vehicles used for terrorist attacks, without any type of fixing to the ground.

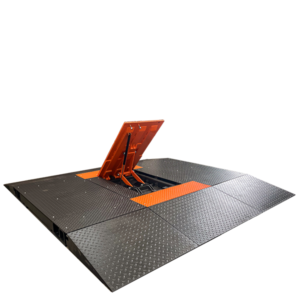

NEW! The new Road Blocker M30 is the optimal solution for safe and flexible perimeter protection.

The mobile road blocker comes in a practical modular system and enables flexible combination of individual modules depending on requirements. This makes it simple to combine modules with retractable alarm contact element with modules for pedestrian passage. With a barrier height of approx. 800 mm the mobile Road Blocker M30 secures passages and provides maximum safety while offering a high degree of flexibility in areas requiring special protection.

ROAD BLOCKER MOBILE IS CERTIFIED ACCORDING TO THE LATEST STANDARD FOR MOBILE ACCESS CONTROL DIN SPEC 91414-1 AND IWA-14 AN ISO 22343-1:2023.

FEATURES:

- Road Blocker M30 mobile vehicle barrier in a practical modular system

- Free combination of modules with retractable element and modules for pedestrian passage

- Barrier height from the ground approx. 800mm

- Maximum safety and flexibility, it does not require fixing to the ground

- DIN SPEC 91414-1 and IWA14 certified (vehicle of 7500Kg at 50Km/h – K4/M30 level)

- NEW! ISO 22343-1:2023 certified (vehicle of 7500Kg at 50Km/h)

- Can be combined with the OktaBlock temporary bollard

The temporary „Oktablock“ bollard is certified as a single-element according to the international Crash test standards: BSI PAS68: 2013 and IWA-14-1: 2013 Crash-Test Level „N2 / N2A“. The Crash Test is carried out with a class N2/N2A truck of 7.500Kg mass which impacts against the bollard at a speed of 50 km/h. The resulting impact energy is about 700,000 Joules.

The certification is also valid for installations with multiple Oktablock bollards, since the crash test was done on a single element.

For the installation no civil works are required, which are essential instead in the case of automatic and fixed bollards. No anchorages in the road surface or the laying of power cables are required for fitting Oktablock.

Thanks to its geometry, there is no predefined impact side and Oktablock can therefore prevent vehicle collisions from several sides outside the protected area. The Oktablock design is deliberately simple and therefore not perceived as „threatening“.

Furthermore, the innovative Oktablock bollard is tamper-proof and requires no protection before and during the event.

Actual product may differ from image shown