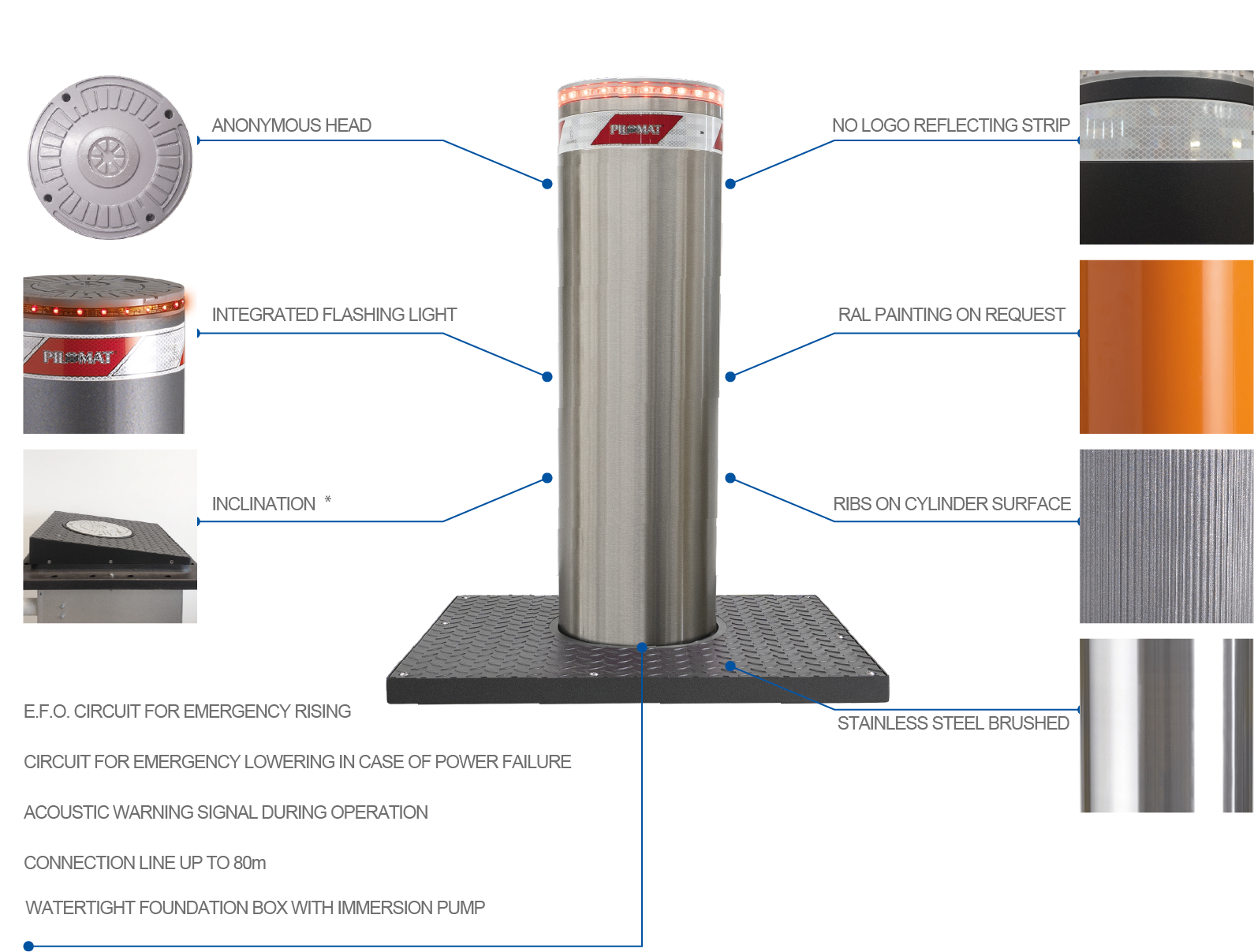

K12/M50 EMB SERIES

The EMB series automatic bollards are unique on the market because they are operated by a brushless motor, a wear-resistant technology that guarantees a long life, ensure constant performance and therefore significantly reduces maintenance interventions.

These electromechanical bollards belong to the High Security range, which includes solutions designed for areas of maximum security such as government buildings, airports, areas for events or other sensitive areas.

Certified ASTM F2656-07 – PAS68: 2013 – IWA-14: 2013

Brushless motor: this technology guarantees high efficiency and constant performance at any temperature and climatic condition but above all it is ideal in intensive use.

Reduced maintenance : Times and costs are lower thanks to easily accessible components and to more configuration simple.

Reduction of environmental risk: the electromechanical bollards can also be used in conditions of very strict environmental constraints, in total respect of the environment.

Silent operation: The emission of sounds is reduced considerably thanks to the “soft” start and stop.

- Company Driveways

- Industrial Driveways

- Research Centres

- Embassies

- Police Headquarters

- Military Bases

- Ministerial Buildings

- Sensitive Sites

The goal of this test is to check that an active bollard system is capable of operating for 200,000 continuous cycles, without failure of any component necessary for continued operation of the bollard. Cycle testing shall be performed in configuration where the automatic bollard itself is located, in outdoor location that will expose unit to full sunlight and effects of climatic conditions at test facility (pollution, rain, snow, sleet, etc.).

Nowadays most of the manufacturers of automatic rising bollards on the market declare that the use frequency is 2000 cycles/day, this means that their product is designed for an intensive use (about 83 cycles / hour). Thanks to this proof not only will we prove that our 275/M50EMB-1200A automatic bollard is three times more resistant, but also that it allows for reduced maintenance actions.

Discover all the accessories

for these automatic bollards

discover the examples of

installation dedicated to these automatic bollards.

Actual product may differ from image shown